“River Ice” vs. “Freezer Ice”: The Advantage of Lab-Grown Diamonds

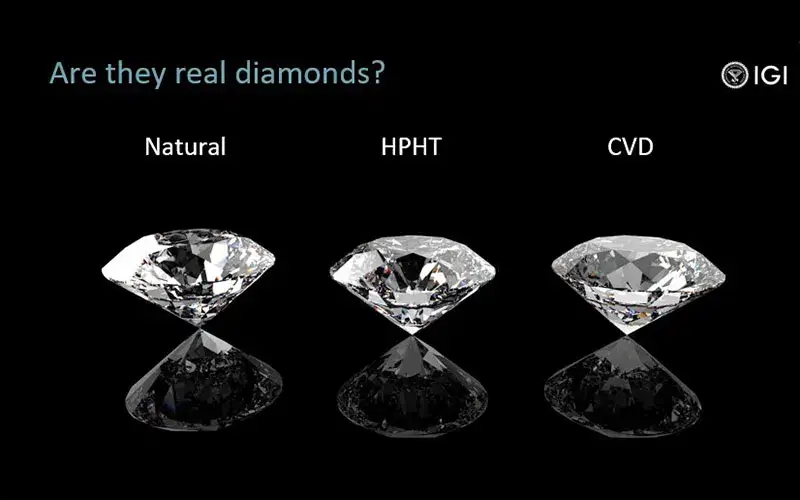

In today’s world, the only thing that can challenge diamonds is diamonds themselves. Lab-grown diamonds offer a choice that is, in many ways, “more perfect than perfect.” The difference between natural and lab-grown diamonds is like comparing “river ice” with “freezer ice”: the same substance and identical crystal structure, but produced through modern technology. Lab-grown diamonds cost only one-third of natural diamonds while retaining the same hardness, durability, and resistance to corrosion. Beyond jewelry, they are also indispensable in advanced manufacturing—ranging from cutting tools to precision instruments—thanks to their stable supply, competitive pricing, and reliable performance.

Consumer acceptance of lab-grown diamonds is rising rapidly. In China, custom jewelry sales are booming. Buyers see them as genuine materials without the stigma of being “fake,” and they can enjoy the look and social value of large-carat rings at a fraction of luxury brand prices. This positions lab-grown diamonds as a middle ground between natural stones and low-cost imitations. Meanwhile, the myth of scarcity surrounding natural diamonds is eroding. De Beers, once the global diamond giant, reported a net loss of $245 million in the first half of 2024, a clear sign that the lab-grown market is reshaping industry fundamentals.

China’s Henan: The Core of the Global Diamond Supply Chain

China’s synthetic diamond industry is highly concentrated in Henan Province. Between 1985 and 1993, Henan established 15 joint-venture plants, laying the foundation for the nation’s leadership in superhard materials. Though counties like Zhecheng and Shangqiu may seem obscure to outsiders, they have played a decisive role in the industry’s rise.

One of the earliest pioneers, Jinzhang Feng, left Zhengzhou Research Institute to found the Shaoyuan Diamond Plant in Zhecheng. Known as the “Huangpu Military Academy” of synthetic diamonds, it trained a generation of skilled workers. Among them was Dayong Shao, who later founded Power Diamond, now a listed company. Meanwhile, Yellow River Industrial in Changge partnered with the Zhengzhou Institute to create Zhongnan Diamond (Yellow River Cyclone), which has become China’s largest producer of synthetic and lab-grown diamonds.

Today, these towns produce staggering volumes: 2.5 billion carats of synthetic diamonds annually, along with 5.8 billion carats of micropowder, across nine major product series and 180 varieties—worth over RMB 15 billion ($2 billion). With technology advancing and capacity expanding, costs have plummeted from RMB 30 per carat in 1965 to just RMB 0.3 per carat today, strengthening global competitiveness.

China, India, and the U.S. : A Global Division of Labor

The rarity of natural diamonds defined the past century, but the global division of labor in lab-grown diamonds is shaping the present.

China dominates upstream production of rough lab-grown stones, supported by Henan’s complete industrial ecosystem. India retains overwhelming strength in cutting and polishing, controlling nearly 90% of midstream capacity. The United States stands as the largest consumer market, driving demand growth.

This triangular balance has brought lab-grown diamonds from laboratories to mainstream commercial markets within decades.

With falling costs and increasingly sophisticated processes, lab-grown diamonds are no longer just substitutes for natural stones—they are emerging as critical materials for advanced manufacturing and new technologies. The dynamics of this global supply chain will define their future value.